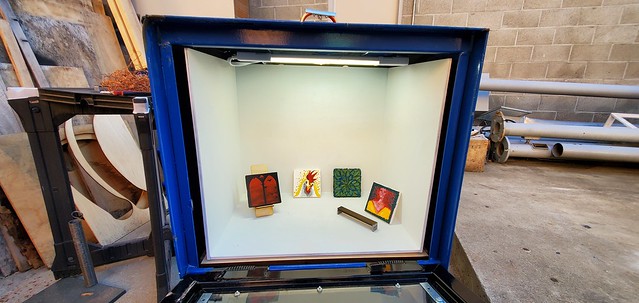

Spring 2024 is already maybe the most vibrant semester in recent memory, even taking into account pre-pandemic semesters. Lots of energy in our student community, and lots of interesting projects, including our Free Little Art Gallery, for which we held an opening event where some folks dressed up for the occasion, and for which we had live music (provided by Lorenzo, a talented musician from our students community and Innovation Center regular).

We hung our 4th (or 5th?) show at the end of last week, including art from students, staff and families of staff, community organizations, other FLAGS in the U.S., and folks from a Northern California retreat center.

The guest book we implemented says it all:

The maker-centered learning (MCL) professional development for teachers project I’ve been working on with John Pellman (Director of Curriculum and Instruction for Capital College & Career Academy) and the Sacramento County Office of Education (SCOE) is picking up speed. We held last month’s session at a fabulous space called Community Shop Class in the Oak Park area of Sacramento.

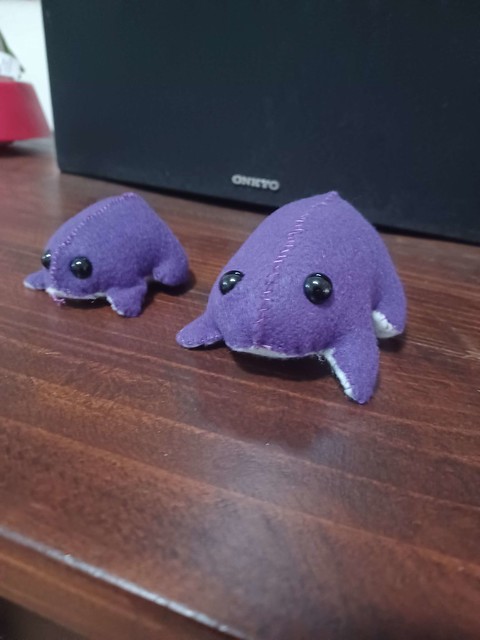

For our first student-led workshop since lockdown, Rox showed folks how to make plushies.

Adorable.

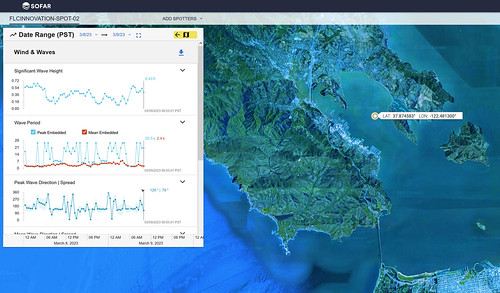

We’ve been flying our surveying quadcopter regularly to document construction progress on the new science building, which is coming along nicely.

Depending on many, many variables (far outside of my control), there’s a possibility that we might be able to expand the Innovation Center into the labs and classroom spaces that will be vacated once this new building is up and running.