Rebekah and Nathaniel (students, Innovation Center employees, the finest people you’d ever want to meet) completed the University Innovation Fellows program:

The University Innovation Fellows is a program of Stanford University’s Hasso Plattner Institute of Design (d.school). The program was created as part of the National Center for Engineering Pathways to Innovation (Epicenter), a five-year National Science Foundation grant.

The three of us recently attended the multi-day UIF Meetup culminating event. On day one, at the hotel in Sunnyvale, we boarded buses and headed to Google for a day of tours, guest speakers, and design thinking challenges. Highlights included a tour of the The Garage, Google’s in-house makerspace, and a thought-provoking talk from none other than Ray Kurzweil.

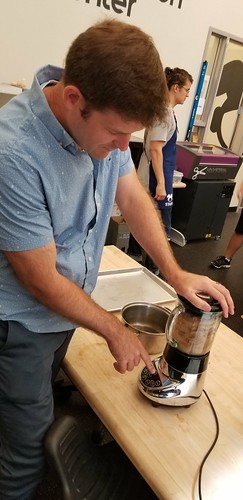

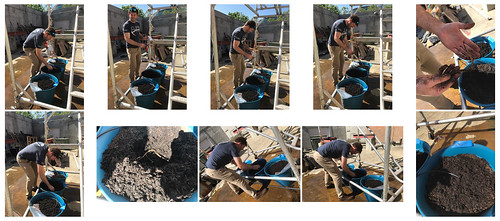

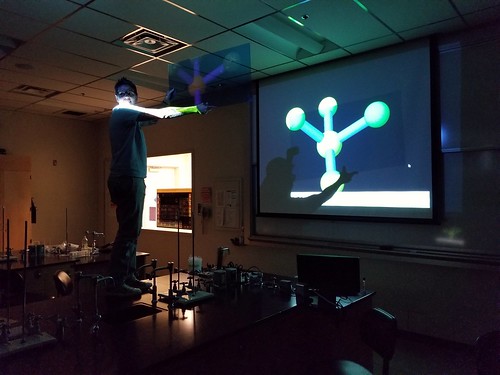

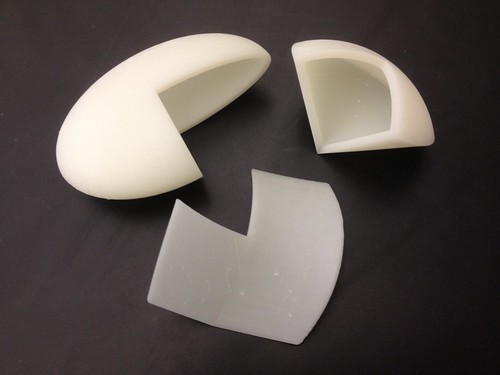

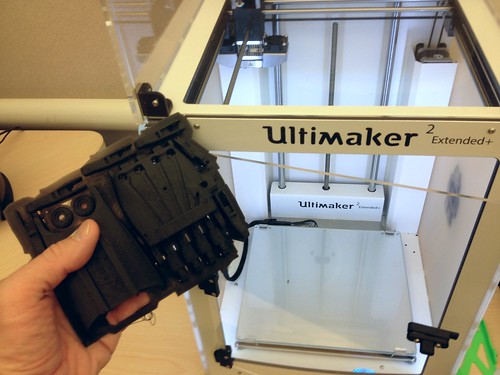

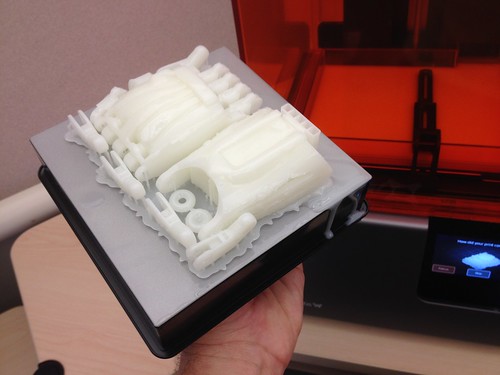

Day 1 photo gallery:

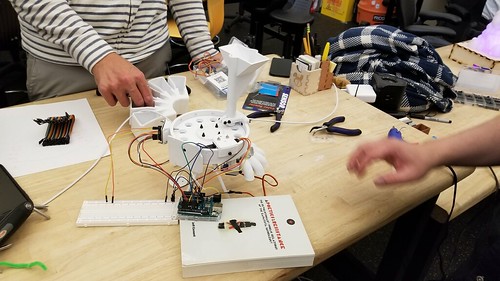

Days two and three were held at the d.school at Stanford. Of particular interest to our work in the Innovation Center were discussions by d.school students and faculty about the way that the physical space communicates expectations, and in particular the design considerations employed to make the d.school a flexible environment for all kinds of activity, from meetings to design thinking to prototyping. I took a lot of pictures of signage and furniture!

Day 2 photo gallery:

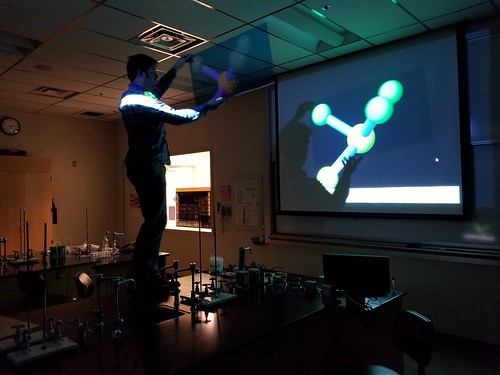

Day three began with taiko drumming, and a brilliant presentation by Ge Wang, electronic musician, inventor, and creator of the ChucK programming language. The rest of the day was spent working through a design challenge, with technology and music industry experts, including August de los Reyes (designer of the X-Box and lead designer at Pinterest), and representatives from the Common Ground Foundation and Pandora circulating and interacting with students.

Day 3 photo gallery:

An intense experience to be sure, and Rebekah and Nathaniel and I left with a deeper understanding of Design Thinking, and of the many ways that the physical environment can be used to facilitate communication and problem solving, lessons that we’ll employ as we continue to build out Innovation Center offerings.