Following our first successful public pour, we have committed to a quarterly brew, to be served at a series of “Art of Wine” events for Harris Center for the Arts members. The first of these will be in late August, so we gathered in the Innovation Center to brew another batch of our Kveik Pale Ale, and a Dry Irish Stout. As it happens, our hops were ready for harvest, so we started the day up in the bines, gathering flowers from our Cascade and Willamette plants.

We weighed and measured these, reserving some to be added “wet” to the pale ale, and the rest we put in the dehydrator to use in some future brew. 564 grams in total.

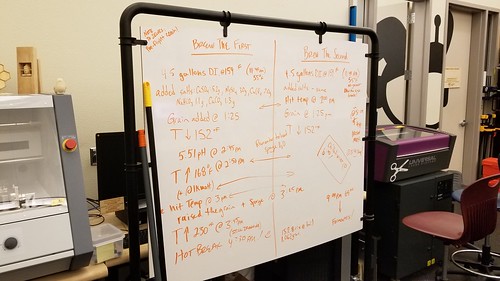

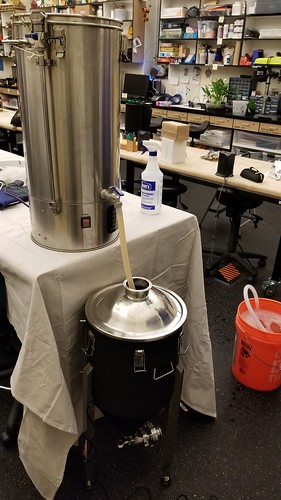

The water built – we start with DI water, and Max adds salts and things to create the ideal water for the particular recipe – we set about brewing. Brewing beer is a lot of waiting around, and a lot of cleaning and sanitizing. We got a chance to try out the new keg washer, which works a treat.

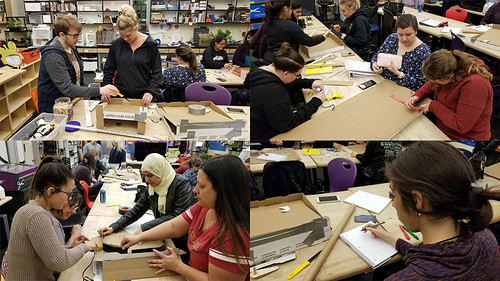

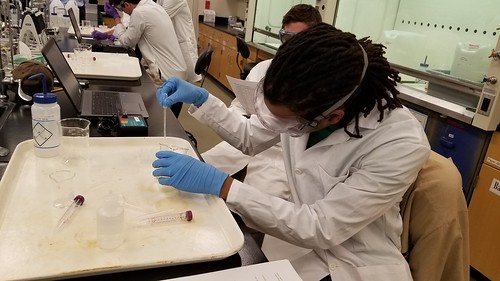

We were joined this brew day by Nicole and John, both students and Innovation Center staff.

Each of them had sparging duties.

Here are the hops in their natural habitat.

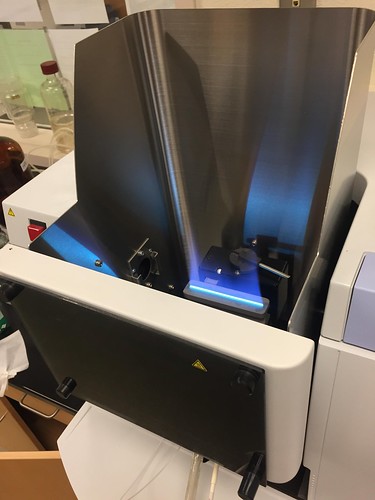

Of all the gear we’ve been able to acquire, the counterflow chiller – the black coil below, just left of the Robobrew, which is used to bring the hot wort down to pitching temperature – has done the most to improve efficiency, and to reduce the amount of water required as part of the brewing process. An absolutely essential tool!

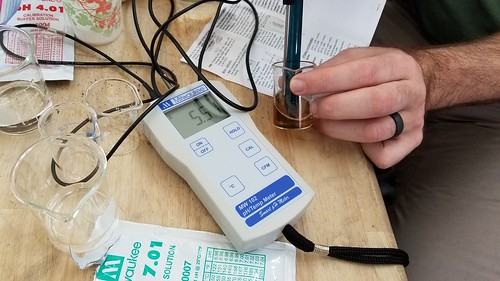

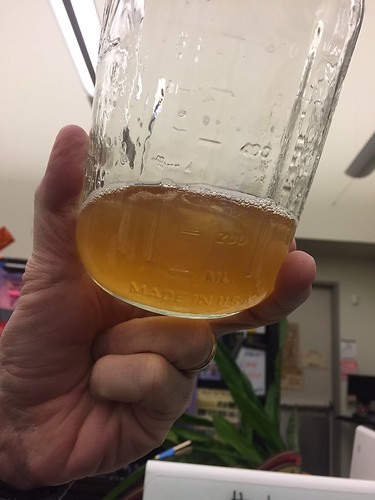

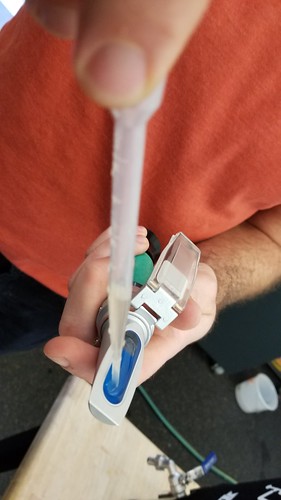

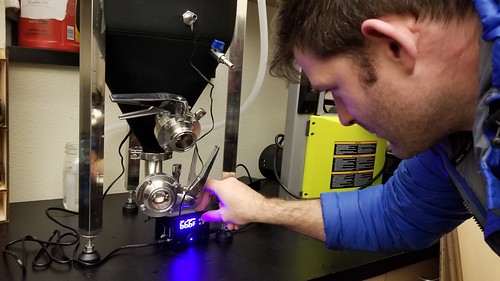

With the beer into the fermenters, and safely housed in the Spider Shed, and with all the brewing gear clean and stowed, Max and Nicole took samples of our prior batch of lavender kombucha and beer…

after which Max entombed them in glass.

We’ll do this for each of our brews, and put them in a yet-to-be-designed UV-resistant display case.

More photos from the day…