Building on the initial success of casting pewter into laser cut forms, I spent some time this afternoon prototyping some coins, with the ultimate goal of creating limited edition thank you gifts for special guests and benefactors.

I created the file for the laser cutter using Illustrator, reversing the text on the face plates, and adding a sprue and two vents into the middle piece, which is sandwiched between the two outer squares and defines the outline of the coin.

Here are the pieces, cut out of 3mm plywood….

…and the first pour.

Not bad, but with some voids up near the ears and some loss of detail in the letters.

I decided to melt this one down, and make some changes to the forms to try and get the metal down into the mold faster.

There are apparently formulas for sprue sizing, but I just decided to try making at a wee bit bigger. I also increased the size of the original vents, and added a couple more.

Better, but still some detail loss up near the top.

For the next iteration, I decided to flip the outside plates upside down, the thought being that any detail loss at the bottom of the coin would be less noticeable than at the top. I also remembered to char the detail plates – a thin layer of carbon seems to function as a release agent.

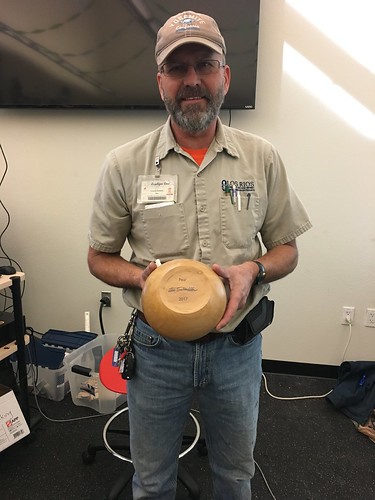

Success! I removed the sprues and vents using flush cutters, and performed an initial polish with fine steel wool.

A really good prototype in hand, I decided to try different kinds of wood for the forms. Here’s walnut.

Not great. Next, I found a small scrap of fine-grained wood – not sure what, exactly – but I only had enough to engrave the plates, so I used the standard birch middle piece.

The metal picks up the grain of the wood, and this being a much finer grain, the result was a very shiny and smooth surface. Definitely an avenue worth exploring in future versions.

I did one more test, spraying ingot release spray on the detail plates. This caused the metal to boil and bubble, resulting in an interesting (but unusable) outcome.

Really pleased with the prototype coin, and I’m excited to continue perfecting this technique, and to finding other applications for molding metal using multi-part laser cut molds.