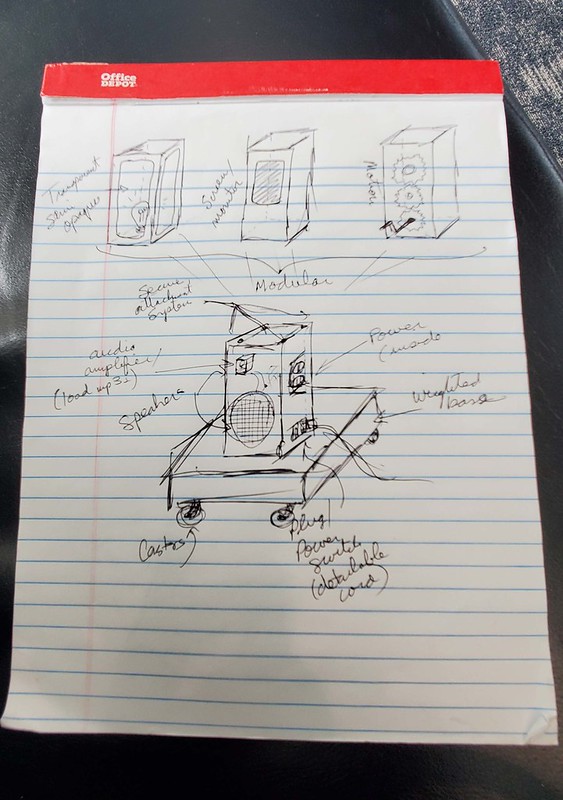

The Innovation Center is collaborating with folks from the Equity Center, the PEAC²E (Peer Engagement for Achievement, Culture, Connection and Excellence) program, and Diane Carlson (Sociology) on a Peace Pole project. One of the many ideas that has emerged from the collaboration is to create a modular mobile “peace pole platform,” essentially a design specification and a set of affordances that will enable members of the college community – disciplines, student groups, classes, anybody – to create art and interactive content for display.

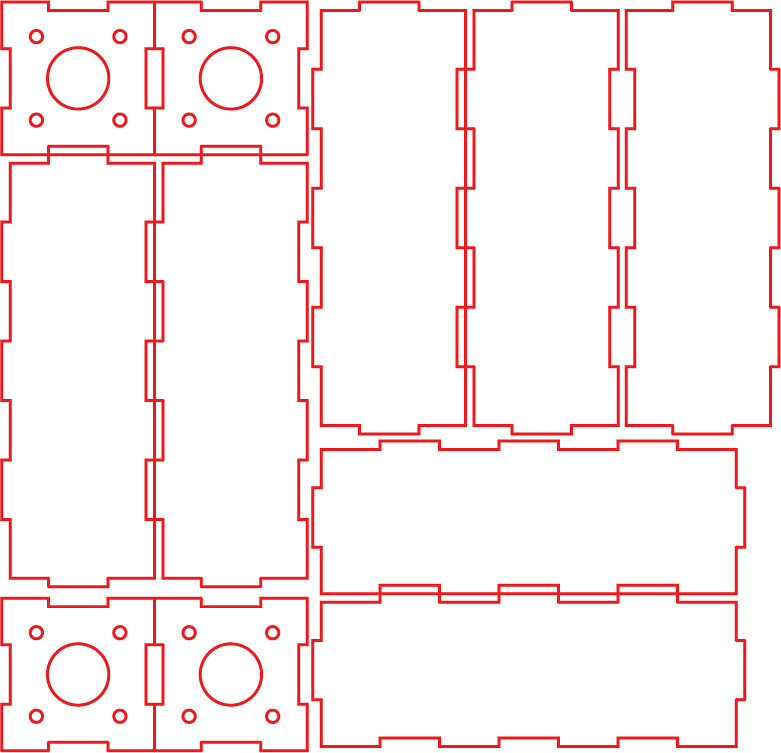

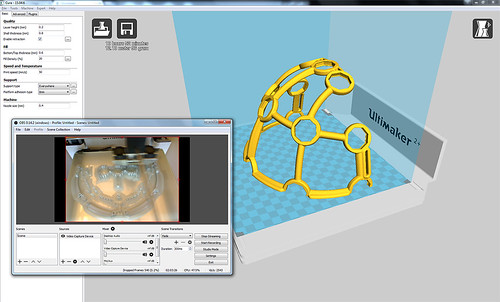

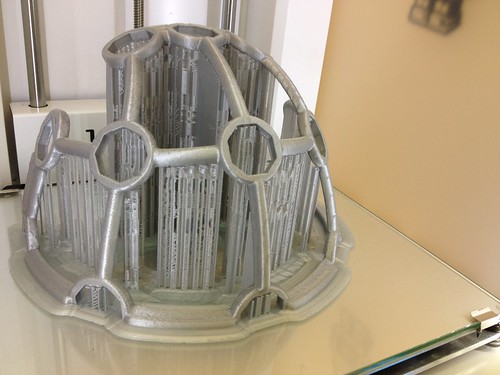

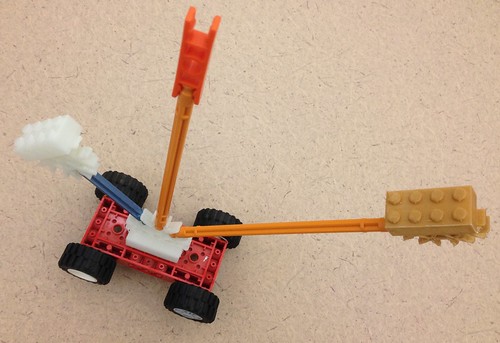

Spent the day yesterday in the Innovation Center (I love having the lab to myself and locking in to the rapid prototyping flow), crafting a 1/4 scale prototype of the mobile modular peace pole platform prototype (M²P⁴?), and in particular exploring how the segments will connect. Nothing especially revolutionary about the basic design; each segment is a simple 12″ x 24″ rectangular box (our big laser has a cutting area of 18″ x 32″), and the pole itself will be three of these bolted together in a concealed way.

The big circle in the middle of each end piece (Illustrator file above) is the access port, and so I think I’ll be able to reach in and connect them together with bolts. There are other ways of creating access panels from the outside – I’m thinking magnetic – that I might explore just to make the connection process simpler.

Three of these stacked will be about 6′, and provide 12 possible faces for art and expressions of peace.

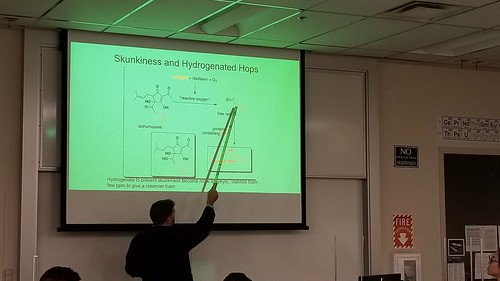

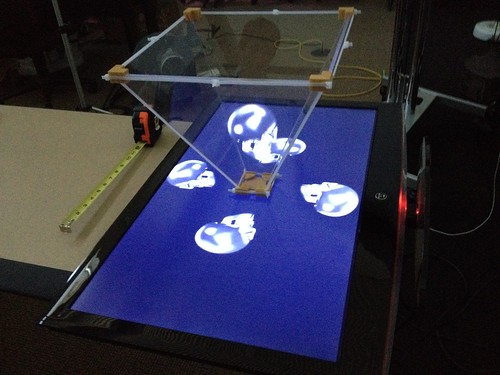

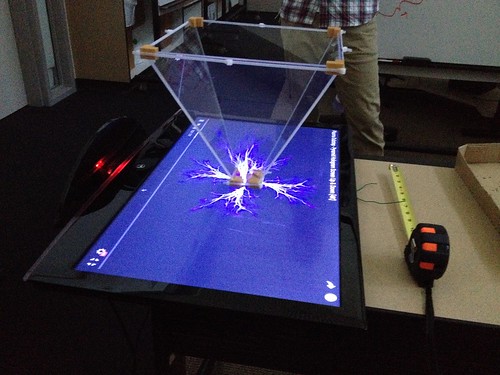

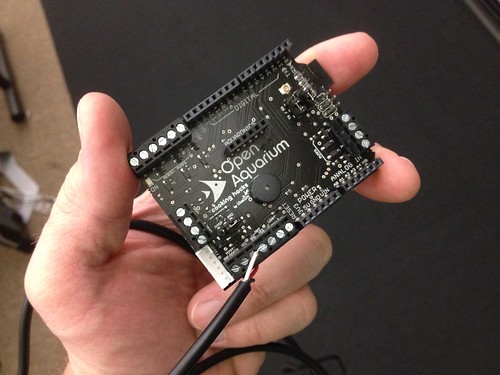

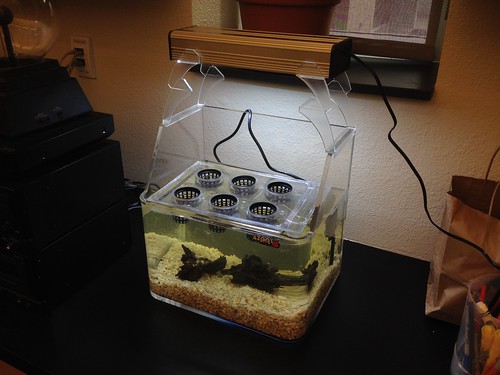

Version 1.0 will be “static” – crawl, walk, run – but the long-term goal is to have the base of the unit equipped with power, sound, and a Raspberry Pi or similar, such that folks have a set of givens they can design for. Think lights and sensors and haptics and interactivity. Two peace poles communicating at a distance? A receipt printer that provides folks with a prayer for peace they can take with them? Lots of possibilities!