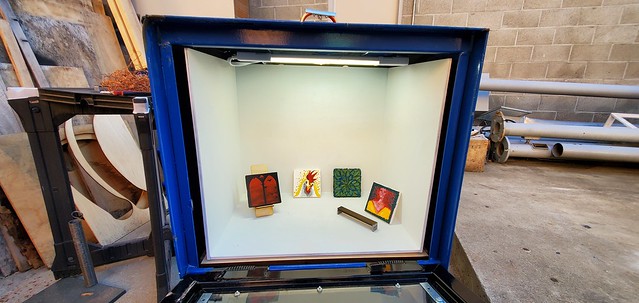

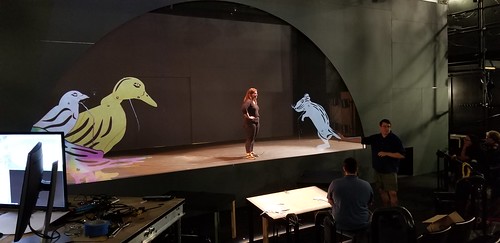

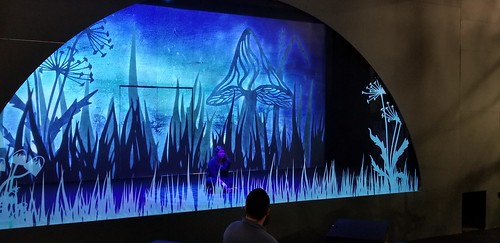

We’ve been working on (until recently mostly just thinking about) a project called The Joy Agenda, which conceptually is an alternate reality layer at the college – something like a combination of geocaching, faerie doors, escape rooms, and Meow Wolf – all motivated by providing opportunities for joy and wonder. We’re getting close to installing the first element of the project, a Free Little Art Gallery, housed in an old newspaper dispenser.

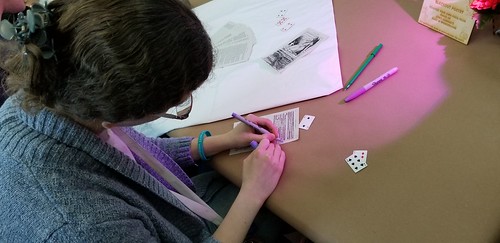

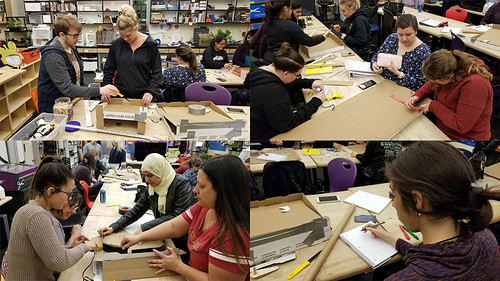

The gallery will be housed in the Library, and folks from the Artist Guild (the college’s arts club), the Equity Center, and our own Innovation Center student community are making and sharing beautiful and tiny – 3″ x 3″ (x 3″ for sculptural works) pieces of art. The plan is to hang a show for a week, and then those works move to the top of the gallery to be taken home by interested art patrons, and another show hung. Rinse and repeat.

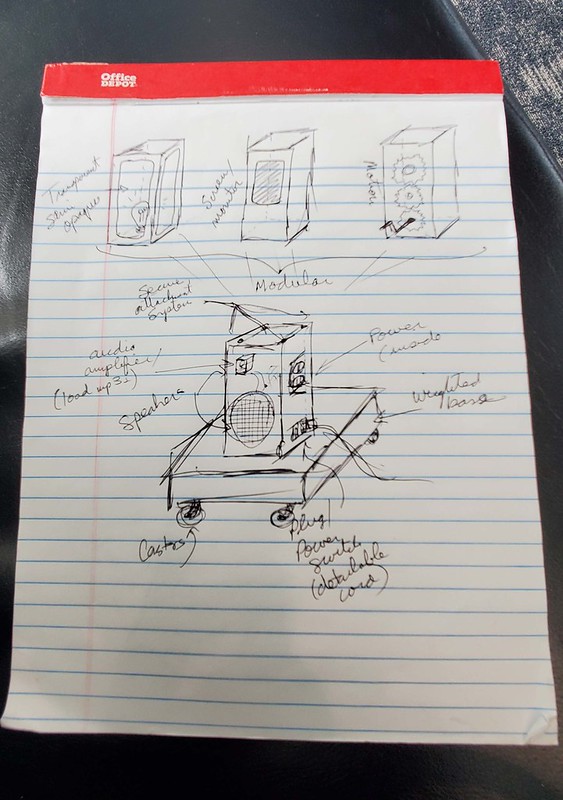

We’ll launch v1.0 as soon as we get enough works for 2 or 3 shows, after which hopefully the project will chug along under its own momentum. Feel free to send some (3″x3″x3″) art, any media, to The Innovation Center, 10 College Parkway, Folsom CA 95630. Phase 2 will see the addition of cyphers and clues and puzzles, leading to fake books in the stacks containing hidden artifacts, tokens for a vending machine filled with arts supplies, and other things we have yet to think of!