The blended SCOBY fruit roll-up leather experiment is finally more or less dry. It took hours and hours in a 120 degree Fahrenheit oven before the water was driven off, and the resulting leather seems strong and beautifully semi-translucent.

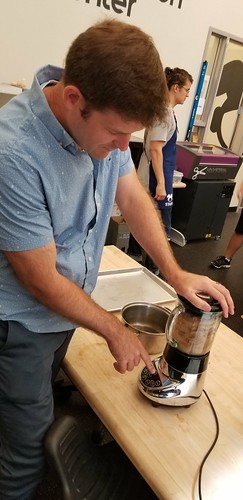

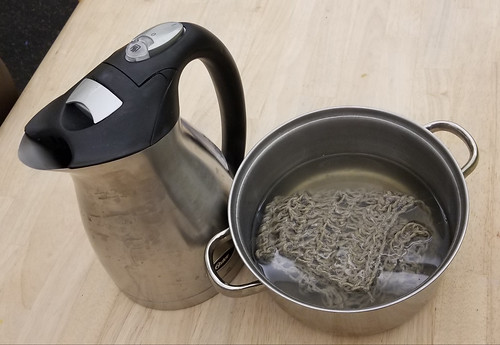

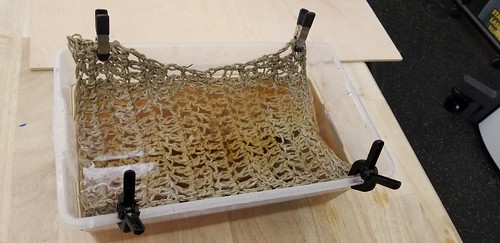

Not sure what exactly we’ll do with it, other than maybe subdivide it for various experiments. Meanwhile, I took a look at the SCOBY net experiment, and was surprised to find that a nice pellicle had formed above the net, and that it had grown through the net at the edges.

I decided to flip it over to see if another layer might grow on top, and then we’ll maybe press it flat to dry, encasing the hemp net between the layers of leather?

For future experiments, it would probably be best to find a way to suspend the net right at the surface of the tea and sugar mixture, so that the pellicle becomes more integrated into the net. Maybe a purpose built, adjustable frame that can be moved up or down to account for liquid loss?