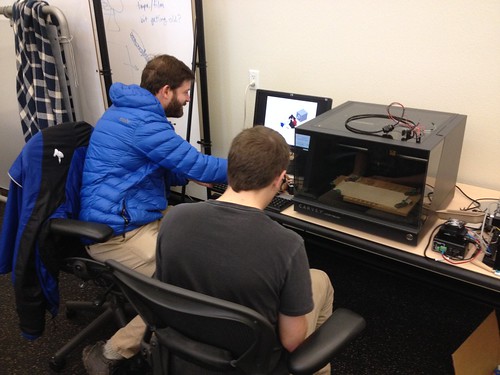

Max Mahoney (Chemistry) and I have been working on version 2 of some UV LED boxes for use in a cyanotype photography activity. We’ve been talking about these for a long time, so it’s nice to finally get to building.

Each box will have three 10 watt 380 nanometer UV LEDs arranged on a piece of aluminum bar stock. We were able to build up the prototype in about a day, working out some of the details about the access hatch, and the arrangement of the lights and so forth.

We also used the new laser to engrave one of the side panels.

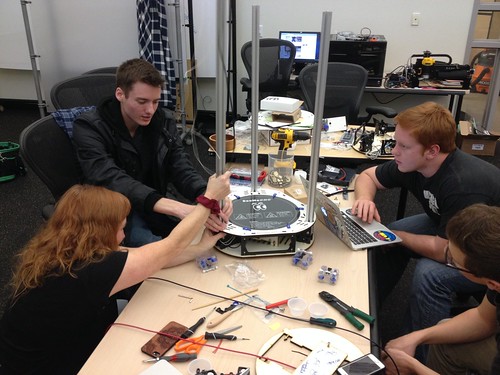

Today Nicole (student) helped out mass producing three additional boxes (for a total of four).

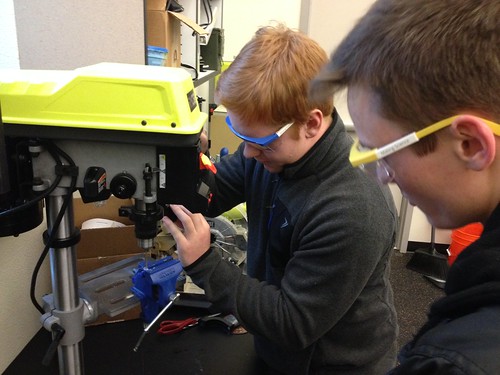

As it turns out, these LEDs get HOT, so we brainstormed some fan arrangements, and settled upon a design. We quickly developed a diagram using Illustrator, running a paper prototype on the laser to ensure that our measurements were correct before engraving and cutting the final piece out of 1/4 hobby plywood.

Looking forward to getting these buttoned up and in use at the end of the week!