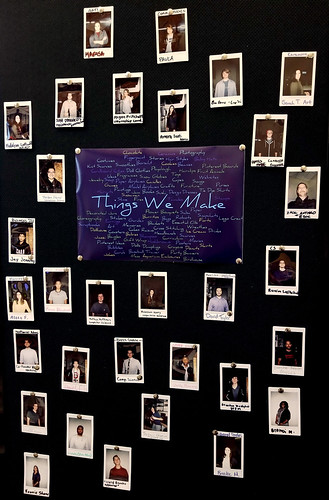

As people enter our space, we’re looking to find ways to communicate answers to the questions “Who belongs here?” and “What kinds of making are valued?” To the first question, we were influenced by some of the practices of Stanford University’s d.school. On our University Innovation Fellows trip last summer, we spent some quality time there, learning about and documenting the ways that physical space can be used to communicate and encourage various ideals and behaviors. The walls of the d.school are covered with photos of people who use the space.

We decided to borrow and adapt that idea, and purchased a little Instax Mini 9 camera…

…to begin to create our own version.

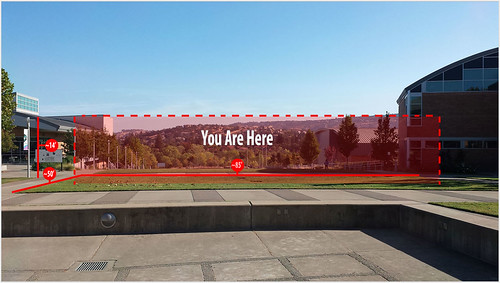

We take photos of visitors and users, and ask them to write their name and major on the bottom of the photo, just using a Sharpie. The goal is to fill up the mobile wall, top to bottom.

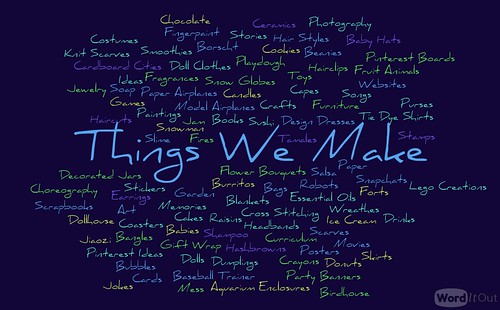

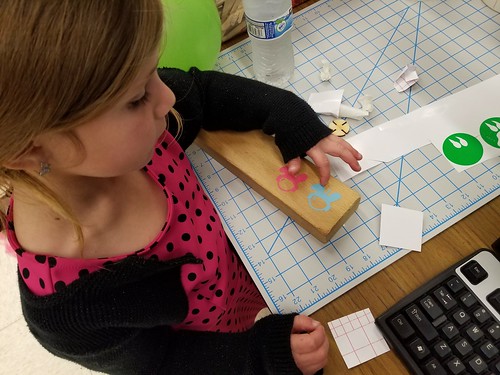

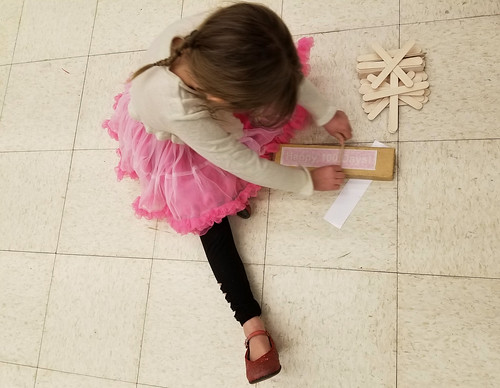

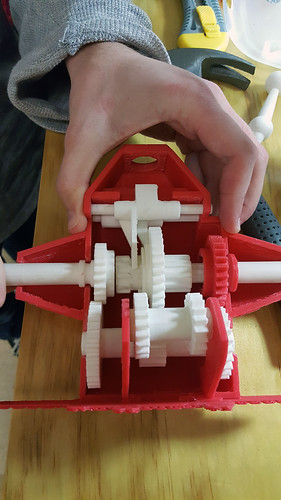

As a multidisciplinary and interdisciplinary space, Making Across the Curriculum is an important part of our mission, and we hold as a cultural value an inclusive vision of making. In the center of our emerging “people wall” is a word cloud generated by Jennifer Kraemer (Early Childhood Education and maker educator champion), based on a student discussion during a “tinkering night” activity for her Constructive Math and Science in Early Childhood Education Class. The kinds of things represented – largely crafts and more “traditional” arts and activities – signal to people the range of making valued in the space, and offer something of a counterweight to the idea that making is only about 3D printers and laser cutters.

The space is always a work in progress, but we hope that through intentional signalling – putting our community loom front and center, for instance – we can continue to create a welcoming and inclusive environment.