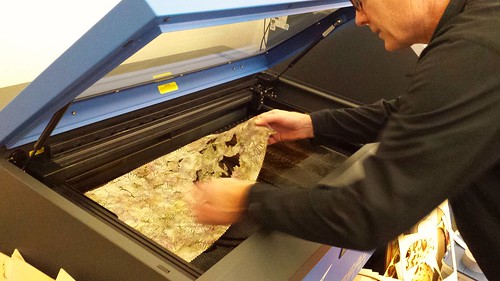

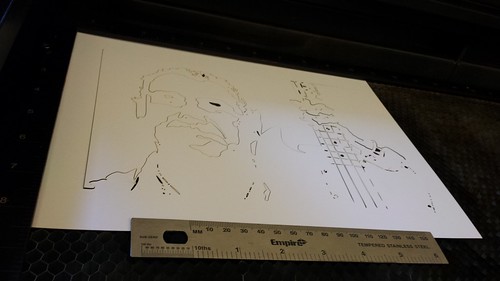

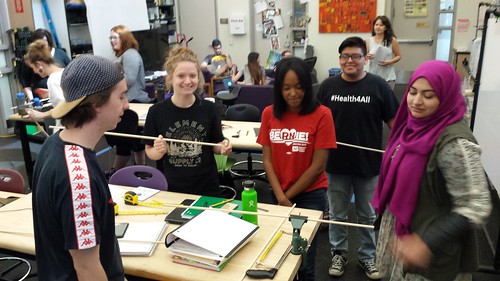

Inspired by our class visit to the Rocklin Mini Maker Faire, where the bulk of our time was spent in the open sewing lab, we spent a recent session of Making Social Change creating applique quilt squares for a collective class quilt. The Theater Arts Department loaned us seven machines to add to the one we have in the Innovation Center, and were able to borrow a few others from students and faculty so that each student would have one to work with. Students started by selecting fabric from a beautiful trove of fabric samples (generously provided by our faculty researcher Jill Bradshaw) and used the laser cutter to cut out 12″ background pieces.

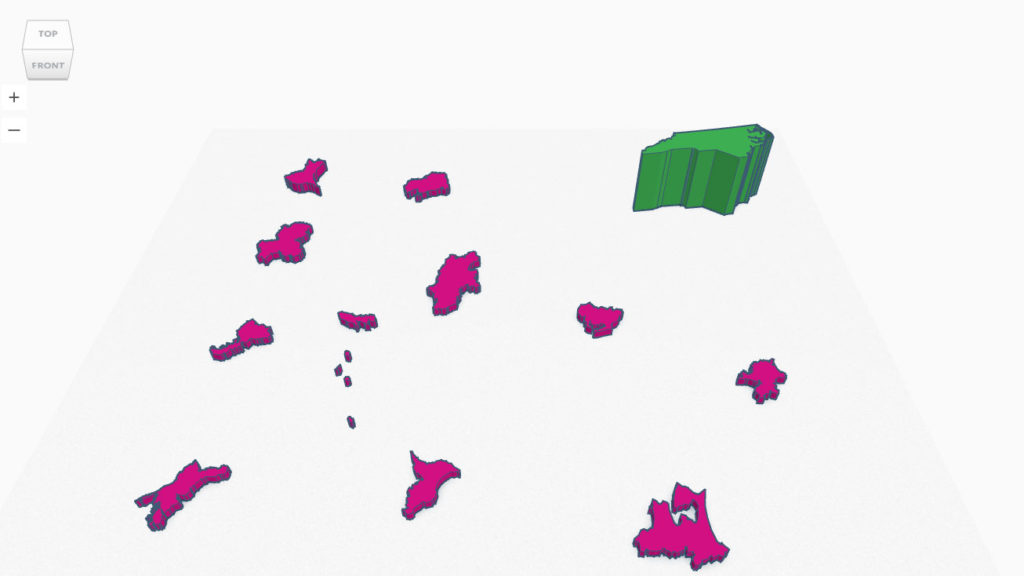

We set up two ironing stations so that students could apply Mistyfuse backing, after which they cut applique shapes and words using the laser cutter (and sometimes good old fashioned scissors).

We had a few folks with sewing experience, and some with none, but students helped each other, and Diane was around to provide guidance and pointers.

Overall a very empowering and dynamic class session! Here’s a gallery of Diane Carlson’s (Sociology) photos from the day: