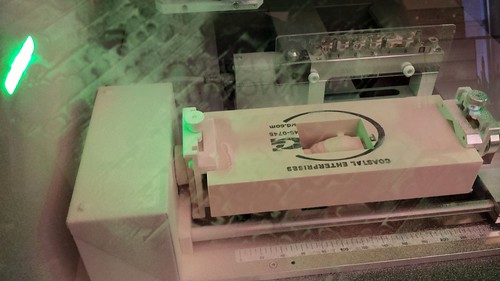

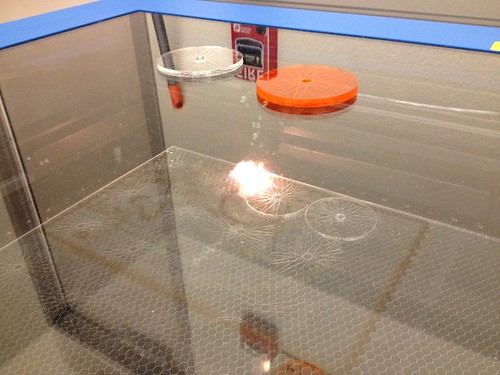

The folks from Paton Group came out yesterday to train us on the Roland Modela MDX-50 we’ve got in the makerspace.

First impressions…

The machine is well-built, and the rotary attachment is especially nice, with precisely machined aluminum parts and the most amazingly smooth bearings. It’s quiet, at least when milling chemical wood. It creates a LOT of dust, and took a while to vacuum after the part was finished. The lighting cues are nice, and it’s easy to monitor the machine from anywhere in the lab. The software – SRP Player CAM – is dead simple to use. I don’t have much experience machining, but I was able to pretty easily set up and run a job after being shown the process just once. It takes standard .STL files, so it should be pretty accessible to those with some 3D printing experience.

The model I picked – Totoro by joo on Thingiverse – was maybe not the best choice, in terms of size (I didn’t make the best use of the material) and because of where the supports needed to be (between the ears, though I learned that custom supports can be built into the .STL file to solve such challenges), but I am happy with the result overall. The chemical wood is a new material to me, and is easily worked with an X-ACTO knife, sandpaper, and files.