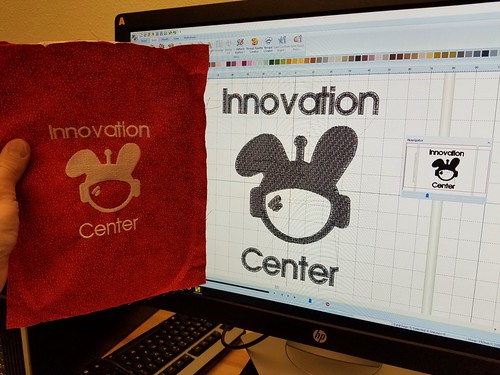

Brie Lindsey (from CCST) was out at the college the other day scouting rooms for the upcoming CCC Maker symposium, and dropped by the Innovation Center. Brie is an accomplished maker, with a lot of experience with sewing and other fiber arts, and she offered to help get the embroidery machine (which has a place to live, now that the fiber arts work table is built) up and running.

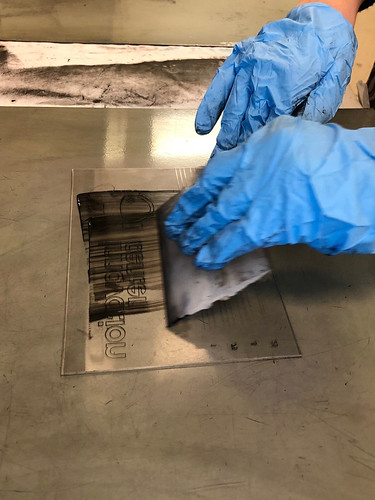

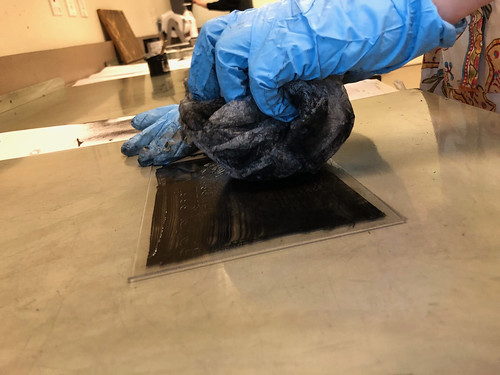

Brie showed me how to wind the bobbins and thread the needle, and after backing the fabric with stabilizer and mounting it to the smaller of the two embroidery frames, we let the machine do its work.

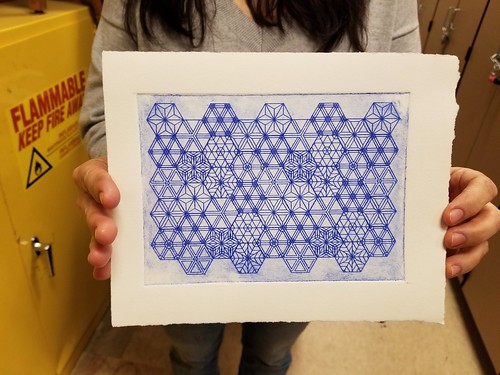

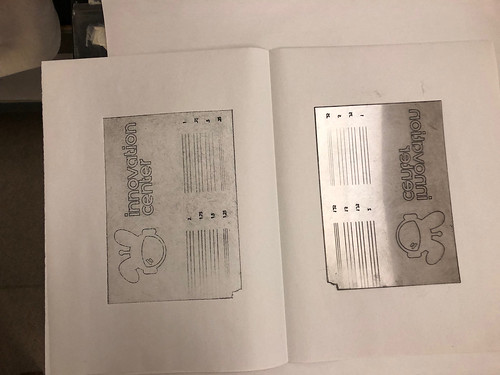

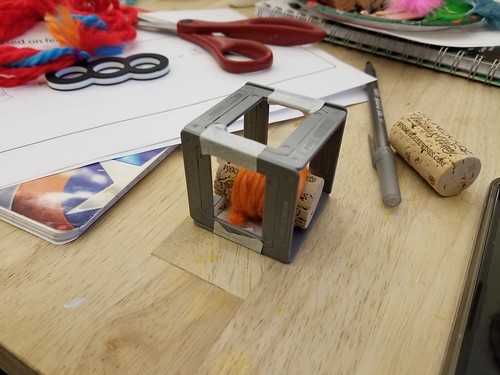

Here’s the view of the finished piece, analog and digital…

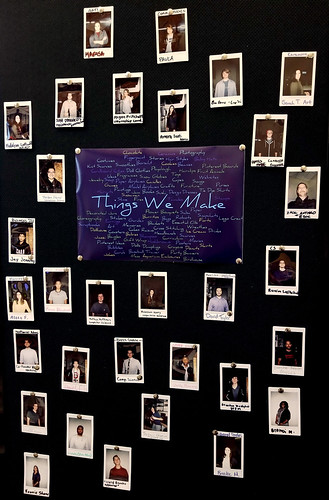

…and here it is framed up in the entrance to the space.

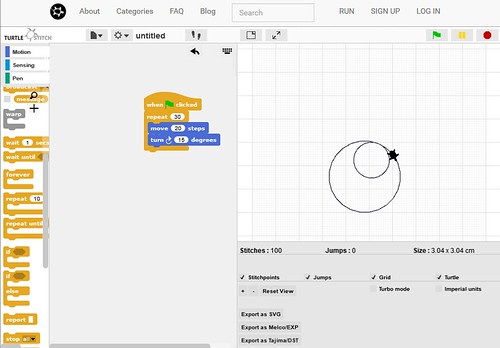

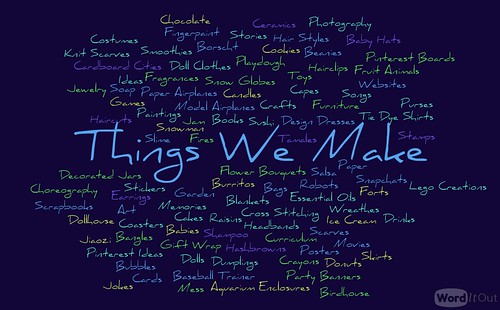

In parallel, I’ve been experimenting with TurtleStitch, essentially a mashup of Snap! (itself inspired by Scratch) and Logo that seems to be a perfect jumping off point for combining basic programming and automated embroidery. From the website:

Turtlestitch is based on a browser-based educational programming language (Snap!) to generate patterns for embroidery machines. It is easy to use, requiring no prior knowledge in programming, yet powerful in creating novel patterns for embroidery. It is useful for designers to experiment with generative aesthetics and precision embroidery as well as tool for innovative workshops combining an introduction to programing with haptic output.

Now that the machine is up and running, my plan is to work with faculty collaborators from Math, CIS, and ECE to develop activities and workshops using the software so that students can both program and sew. Software to stitches.