Student interns just wrapped up three days in the Innovation Center working in teams to solve a business challenge as part of the CCC Maker Makermatic program. Created by our friends at Sacramento City College Makerspace to meet the internship goals of the CCC Maker statewide grant, and coordinated locally by Seeta (FLC’s Innovation Center Internship Opportunities Specialist), the program was an opportunity for students to propose solutions for business challenges in partnership with Solid Ground Brewing, a local brewery and restaurant. Solid Ground also makes wine, and winemaker Scott came out to the Innovation Center to provide context and listen to student presentations.

The night before final student presentations, Max (Chemistry), CJ (student and Makerspace Facilitator) and I worked to create a gift to present to Solid Ground at the close of the event. We decided to design a beer flight sampler display, with custom-etched flight glasses. CJ fired up Safety Scissors (the name for the smaller of our two laser cutters), and we worked out a design that combined Solid Ground’s logo and Nova, our own space bunny logo/mascot/spirit guide.

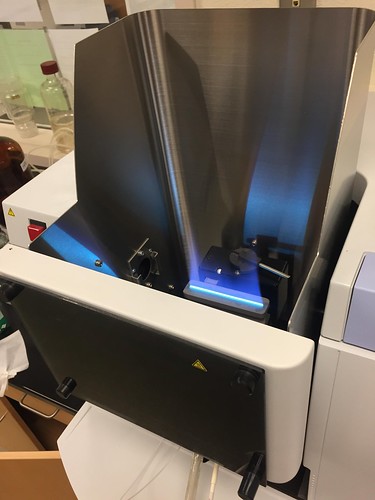

Here Max is evaluating different etching parameters. We didn’t have any beer in the space, so we filled the test glass with a combination of soy sauce and water to provide a little contrast while we worked out the details.

After a few rounds of prototyping – size, placement of thumb and finger indexes, type – we cut, glued, and assembled the pieces.

The glue dry, we sanded away the laser burn marks, friendlied up the sharp edges of the plywood, and sealed everything with cutting board conditioner.

Each glass has a number etched into Nova’s (our space bunny mascot’s) faceplate, corresponding to a numbered position on the flight corral.

At the close of the Makermatic event, we took Scott over to the Spider Shed (our nascent brewhouse) to talk about ways we might work together with Solid Ground, and to sample some kombucha Max had kegged from one of our brew days.

Max has been perfecting some procedures using Atomic Absorption Spectroscopy (AAS) equipment in the Chem lab, and we talked with Scott about the potential to have students work with local breweries to provide water quality analysis as part of our larger FermSci efforts.

We like traditions in the Innovation Center (things like Builders’ Rights – see ROSTOCK MAX V3 BUILD DAY – PART TWO), and Scott became the first brewer/winemaker to sign our (nascent) keezer!