Made some spectacular progress on the aquaponics project, producing a prototype of what will eventually be the light-up infographic built into the base. The team collaborated on a design for a diagram of the nitrogen cycle, and with the help of Ian Wallace (Professor, Theater Arts) and Cameron Hoyt (student and designer of the tank stand), we were able to get the design cut out on the big ShopBot in the scene shop.

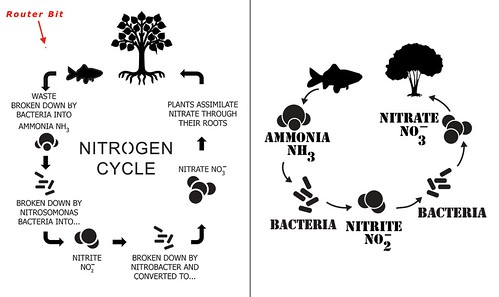

Tools have their own logic, and CNC is no different. Balancing legibility of the design with the properties of the materials and the constraints of router bit size was a learning experience. The initial design was text heavy, but the 1/8″ bit introduces some size constraints. That is, the text has to be large enough for the machine to cut. After consulting with Ian, I scaled up many of the lines, adjusted the font, and created a little 1/8″ dot to drag around the image as a simulated router bit. The original is on the left, with the revised version on the right (below).

Ian took the draft diagram and ran it through software to create the tool path. Some scale work still to be done, especially on the text, but we decided to run a test cut anyhow.

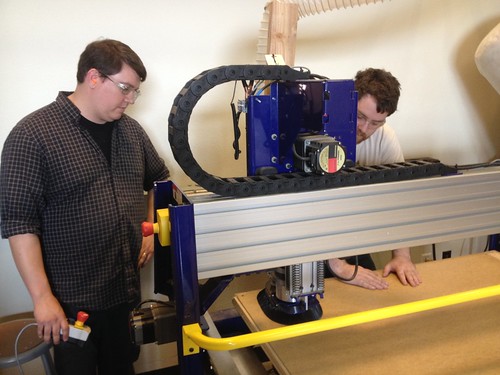

I watched and learned as Cameron and Ian set up the ShopBot and got things ready to carve…

…after which I babysat the machine, which took about 30 minutes to cut out the prototype.

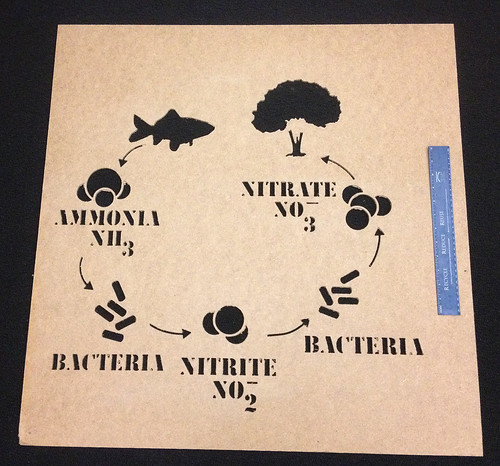

Below is the prototype, after a little cleanup with a knife, sandpaper and a file.

There’s still some design work to be done, and some tightening and scaling to make the diagram legible, but we were very pleased with this rough version. Always be prototyping!