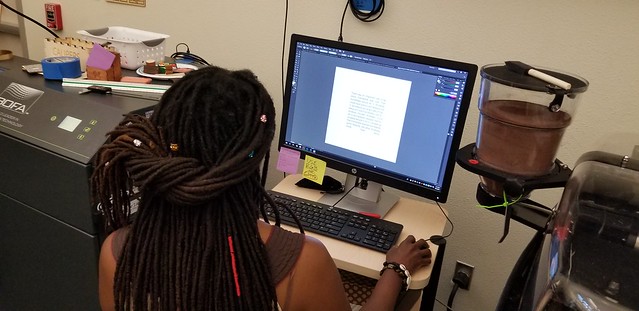

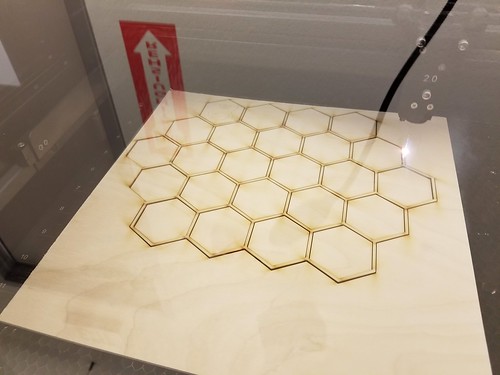

Victoire (Communication and Media Studies) dropped by the lab today, and shared an idea she had about creating a puzzle as part of her Group Communications class in the fall. She brought with her a piece of paper with the “Everybody, Somebody, Anybody, and Nobody” story on it, and talked about turning it into a puzzle. We quickly got to prototyping, first on paper, kicking around ideas about the sizes of the words, the individual pieces, and the puzzle overall. We fired up Illustrator to create version 1, which we laser cut on 1/8″ hobby plywood.

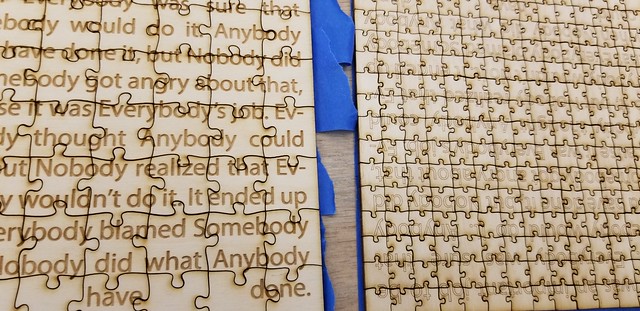

We immediately agreed that the pieces were too small, the words not legible enough. Back to the drawing board, where we more or less quadrupled the size of the pieces, and changed the letters from vector outlines to raster engraves.

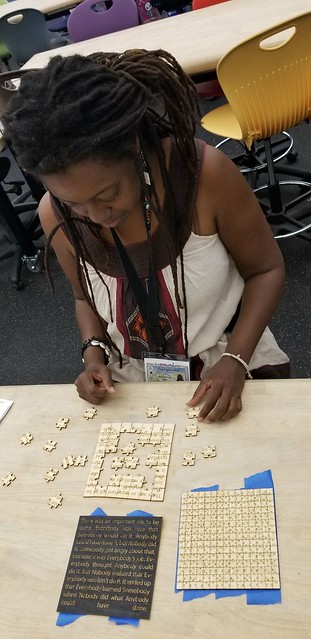

This version felt more or less right, and then I remembered a project Jeremy (Making Social Change student) had done maybe a year ago, spray painting plywood and then laser engraving that for a white-on-black effect. We happened to have a piece of prepared plywood, which turned out to be the best of the bunch.

After test driving the puzzle, Victoire was satisfied with how it felt, and she was able to set up the laser job and produce enough puzzles to take with her for the first day of class in a couple of weeks.

Victoire walked in with an idea, and walked out with a v1 prototype about an hour and a half later, feeling super charged up and empowered. Priceless.