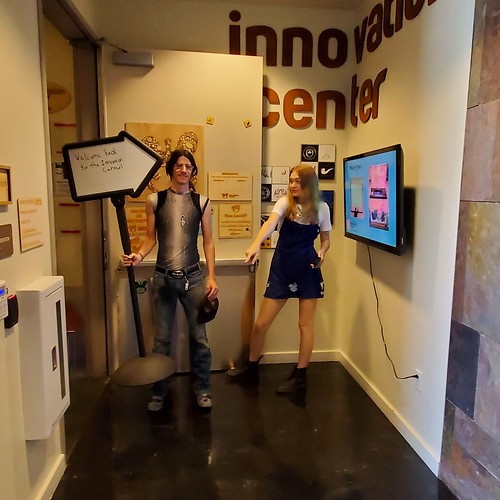

After a few years, the Innovation Center @ Folsom Lake College has once again opened its doors to students!

It took a bunch of work getting to this point, including seasoned Makerspace Facilitators (Sophie and Nicole) training up new staff…

We’ve held some workshops – here Sojourner and Hannah lead a laser cutting workshop.

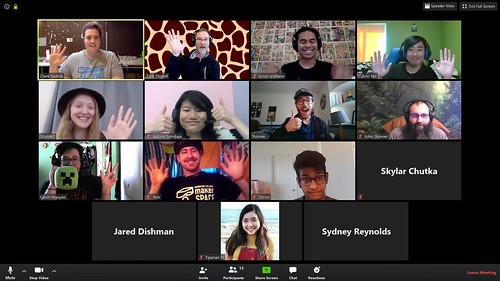

We also hosted the second ever meeting of a new organization – the NorCal Makers Guild – we’re helping get off the ground.

Students from Cordova High (one of our longtime K-12 partners) paid us a visit and drove some robots.

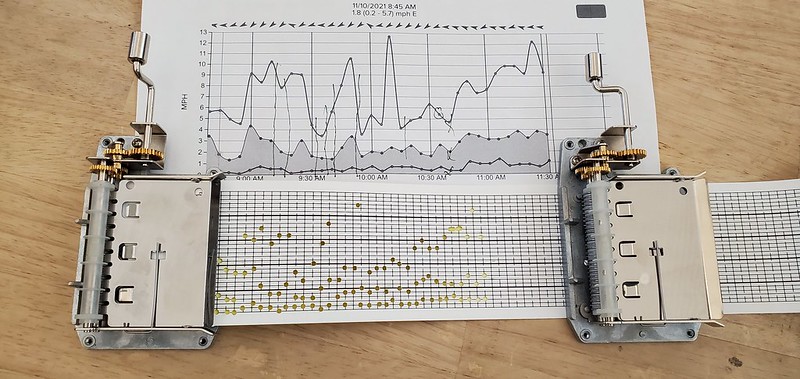

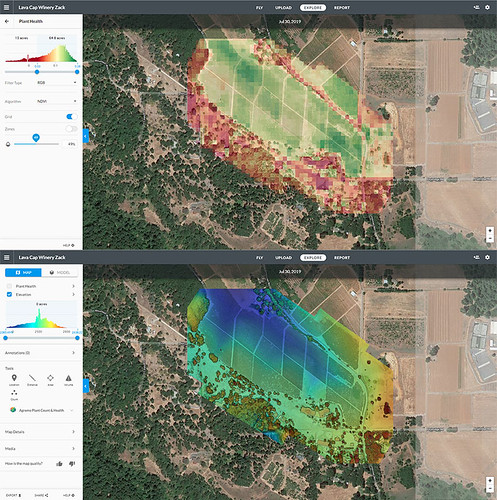

After a few weeks, we’ve got the core of a vibrant maker community emerging, including a new student-led Maker Club (something we’ve never had formally before). Club members recently had the opportunity to fly some of our aerial imaging drones.

Last but not least, we finally got a mini LEGO wall for the front entrance, which makes me incredibly happy.

Thankful to be back!